Clean Air Biosafety Cabinet Manufacturer in India

Biological Safety Cabinets is known as tissue culture hoods, are designed to provide personnel, environmental, and product protection.

A biological safety cabinet is designed for the user, the product, and the environment from aerosols resulting from the handling of potentially dangerous micro-organisms.

It is a negative pressure safety device which generally used in microbiology, biomedicine, clinical research, life science, animal experimental, gene recombination, and scientific research for biological products, teaching, clinical examination, production, and pharmaceutical laboratory.

Through this device, the continuous airflow is discharged to the atmosphere via a HEPA filter. These filtered cabinets are essentially produced to protect against exposure to particulates.

This purifies the air of infectious aerosols but does not allow lessening exposure to chemicals.

The three States of Protection

- Personal Protection from harmful agents within the cabinet

- Product Protection to avoid contamination of the samples.

- Environmental Protection from contaminants contained within the cabinet.

Biological Safety Cabinets are classified into three classes based upon their containment capabilities when working with biological agents.

Class 1 Cabinets

Provides personal and environmental protection.

Used when working with low to moderate risk biological agents.

Biosafety levels: 1, 2 and 3

Class 2 Cabinets

Provides personnel, environment, and product protection.

Used when working with low to moderate risk biological agents.

Biosafety Levels: 1, 2 and 3

Class 3 Cabinets

A highly specialized laboratory “glovebox”.

A Class 3 cabinet provides the same protection as a Class 2 but is designed for working with Biosafety Level 4 highly infectious agents and provides the highest level of protection for the environment, product, and user.

Used when you are working with very high-risk biological agents.

Biosafety Level: 4

Explanation of the different Biosafety Levels

Biosafety Level 1 applies when working with biological agents, which pose a minimal risk/ threat to laboratory personnel and the environment.

Work with these types of agents is generally performed in open laboratory cabinets without the use of special containment equipment.

Biosafety Level 2 covers working with pathogenic or infectious organisms posing a moderate hazard.

Examples include Salmonellae, Hepatitis B virus, and Measles virus.

Biosafety Level 3 applies when working with indigenous or exotic agents, which may cause serious or lethal disease via aerosol transmission. Examples include Yellow Fever and Encephalitis.

Biosafety Level 4, applies when working with extremely dangerous, contagious, and life-threatening agents.

Maximum containment and protection are required at all times. Examples include Ebola, the Lassa virus, and any sample with unknown risks of pathogenicity and transmission.

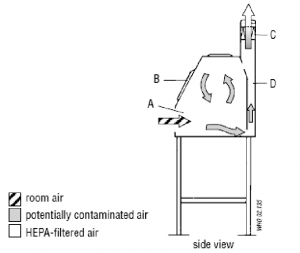

Class 1 Biological Safety Cabinets

The Class 1 biological safety cabinet provides personnel and environment protection for safe handling when working with chemicals and powders.

The air enters the cabinet via the front aperture passing through a built-in exhaust fan, HEPA, and/or Carbon filter, thus providing operator and environmental protection. The air then exits the cabinet at the rear of the work surface.

The escape of any airborne particulates generated within the cabinet is therefore controlled by means of the inward airflow through the front aperture and by filtration/absorption of the exhausted air.

Unlike fume hoods, the HEPA filter in the cabinet protects the environment by filtering the air before it is exhausted.

A Class 1 Safety Cabinet is not appropriate for handling research materials that are vulnerable to airborne contamination, since the inward flow of unfiltered air from the laboratory can carry microbial contaminants into the cabinet.

In these circumstances, a Biological Safety Cabinet Class II is more applicable.

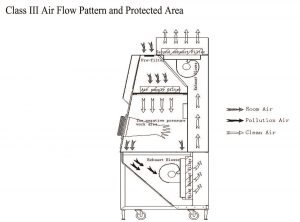

Class 2 Biological Safety Cabinets

The Class 2 Biological Safety cabinet must meet the requirements for personnel, environmental, and product protection.

The airflow is drawn into the work chamber via the front aperture and continues under the worktop and goes up the back plenum, where 70 % is being recirculated through the main HEPA filter to provide downflow, and 30 % exits out through the HEPA filter to exhaust.

The vertical laminar flow Biological Safety Cabinet provides operator protection by means of inflow, product protection by means of downflow, and environmental protection by means of the filtered exhaust.

The Class 2 Biological Safety Cabinet has three key features:

- A front opening with carefully maintained continuous inward airflow.

- HEPA-filtered, vertical, unidirectional airflow within the work area.

- HEPA-filtered exhaust air to the room or the exhaust connected to an external extract system.

As the Class II designs permit different airflow patterns, velocities, HEPA air filter position, ventilation rates, and exhaust methods, classification of type is required to differentiate between the Class II safety cabinet variants.

Types of Class 2 Biological Safety Cabinets

There are two different types (Type A and Type B) based on their construction and configuration.

They are classified according to the percentage of air exhausted to that of air recirculated from the common air plenum.

In addition, the cabinets have different means of exhaust, where some may exhaust air directly back into the laboratory, whilst others may exhaust air via ductwork to an external ventilation system.

Type A cabinets are suitable for microbiological research with the absence of any volatile or toxic chemicals since air is recirculated within the cabinet.

This cabinet type is further sub-typed into types A1 and A2

A1 Biological Safety Cabinet

- HEPA filtered downflow.

- 70 % of air is recirculated within the cabinet.

- 30 % of the HEPA filtered air is exhausted into the laboratory or to the outside atmosphere.

- HEPA filtered air can be exhausted back into the laboratory or to the outside atmosphere with a thimble-type duct connection.

- Alternatively have biologically contaminated positive pressure plenum.

A2 Biological Safety Cabinet

- HEPA filtered downflow.

- 70 % of air is recirculated within the cabinet.

- 30 % of the HEPA filtered air is exhausted either back into the laboratory or to the outside atmosphere with a thimble duct connection.

- The biologically contaminated plenum is under negative pressure or surrounded by negative pressure.

Type B cabinets are hard-ducted to the building exhaust system and incorporate a negative pressure plenum, and are further sub-typed into types B1 and B2.

B1 Biological Safety Cabinet

- HEPA filtered downflow.

- 30 % of air is recirculated within the cabinet.

- 70 % of the HEPA filtered air is exhausted to an external ventilation system.

- The cabinet must be hard ducted into an external ventilation system.

- May have biologically contaminated ducts and plenums under negative pressure.

B2 Biological Safety Cabinet

- HEPA filtered downflow.

- None of the air is recirculated within the cabinet or work area.

- 100 % of the HEPA filtered air is exhausted from the cabinet.

- The cabinet must be hard ducted into an external ventilation system.

- All ducts and plenums are under negative pressure.

- All contaminated ducts are under negative pressure or surrounded by directly exhausted negative pressure ducts or plenums.

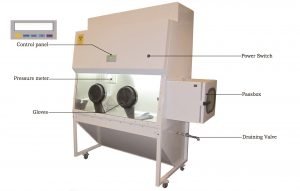

Class 3 Biological Safety Cabinets

A Class 3 Biological Safety Cabinet is an aerosol-tight enclosure with a non-opening, completely sealed, front window, so the operator is separated from their work by a physical barrier.

The cabinet is also referred to as a” Glovebox”.

Work is conducted via long heavy-duty rubber gloves attached to the ports in the front of the safety cabinet in a gas-tight manner.

This allows access and works to be performed on your product within the cabinet without compromising containment

Removal of materials from the cabinet must be through a safety airlock transfer hatch or double door autoclave, which is located on the side of the chamber of the BSC for decontamination.

Interlock or protocols must be used for the autoclave and pass-through doors to prevent both doors from being open at the same time.

The cabinet is designed for work with high-risk biological agents in Biosafety Level 4 laboratories, where maximum containment and protection are required.

Examples include Ebola, the Lassa virus, and any agent with unknown risks of pathogenicity and/or transmission.

When the Biological Safety Cabinet Class III is installed in a Biosafety Level 4 Laboratory or facility, it offers an additional level of containment and safety for high-risk working procedures.

A Comprehensive Solution If You Want To Buy A Biosafety Cabinet

Shree Om Scientific Instruments Clean Air Biosafety Cabinet Manufacturer in India specializes in both standard and customized models of Biosafety Cabinets specially designed to meet the challenging demands of various scientists for individual and specialized research applications.

Our Clean Air biosafety cabinets are maintained in high-quality standards, best in design, and innovative.

We believe to provide a high level of protection to the operator, sample, and surroundings with advanced technology.

With an intensive track document of protection, reliability, and performance, we make the best biosafety cabinets. If you are interested you can contact us…Shree om scientific instruments